Small Cabin, Large Impact: A Case Study in Tracking Whole-building Embodied Carbon

In the mountains of Western North Carolina, the expansion of a wellness and education campus presented the opportunity to study the embodied carbon of mechanical, electrical, and plumbing (MEP) systems. The embodied carbon of MEP systems is generally a gap in industry knowledge fueled by the lack of data and guidance on its collection. By conducting this study on the design and construction of 30 identical guest cabins, we are able to capture the whole carbon story, confirm the impact of sustainable design choices in MEP systems, and contribute to the collective body of knowledge.

In the mountains of Western North Carolina, the expansion of a wellness and education campus presented the opportunity to study the embodied carbon of mechanical, electrical, and plumbing (MEP) systems. The embodied carbon of MEP systems is generally a gap in industry knowledge fueled by the lack of data and guidance on its collection. By conducting this study on the design and construction of 30 identical guest cabins, we are able to capture the whole carbon story, confirm the impact of sustainable design choices in MEP systems, and contribute to the collective body of knowledge.

Background

What is embodied carbon and why does it matter?

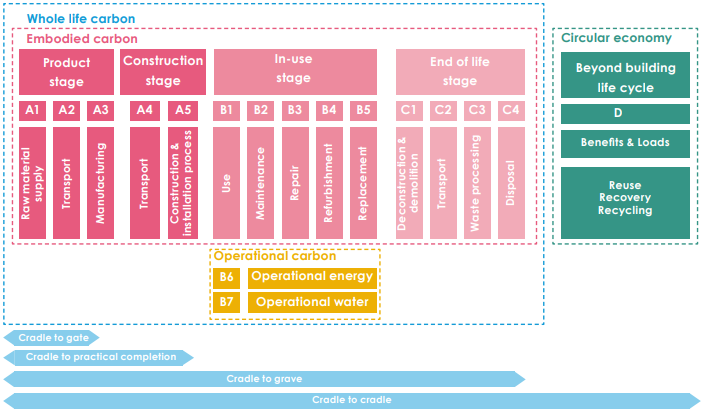

Every product that goes into a building has a price tag — every nail, screw, shingle, and doorknob. While this is true for monetary value, it is also true for carbon dioxide emissions. Every product or material in a building has a certain amount of carbon emissions associated with its extraction, manufacturing, transportation, construction/installation, use, repair, and disposal. Embodied carbon (EC) is the summation of carbon emissions at all these stages — like a carbon price tag.

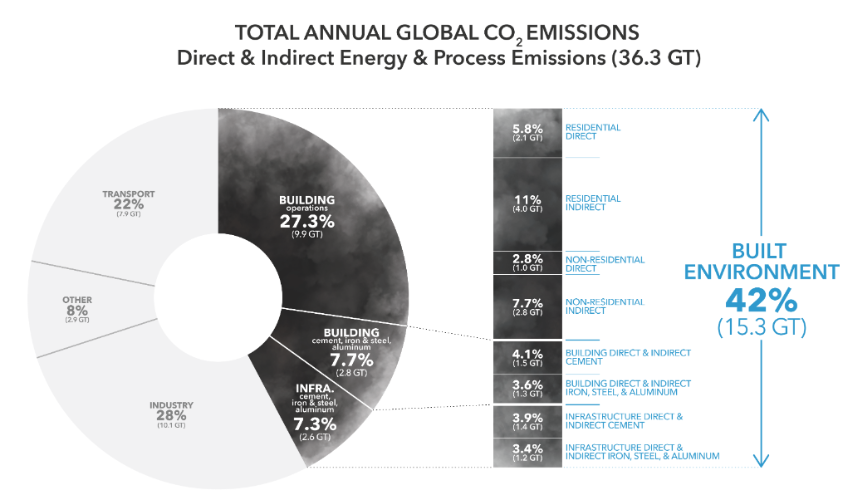

Global temperatures are rising at a rapid rate, and as seen in Architecture 2030’s article “Why the Built Environment,” this is largely due to the increased concentration of greenhouse gases, like carbon dioxide, in the atmosphere. How much a material or product contributes to global warming, or its global warming potential (GWP), depends on its embodied carbon — higher EC means a higher GWP and vice versa. For example, turning iron ore into a steel beam takes a lot of energy (drilling, blasting, refining, casting, etc.) and therefore a lot of carbon, so its inherent GWP will be higher than that of a wooden truss which does not require as much energy to produce. An environmental product declaration (EPD) is a document that outlines exactly how a product is made and the environmental impact of those processes, including its GWP.

Embodied carbon outlined in red. Image courtesy, AIA 2030.

Embodied carbon in the built environment accounts for a significant portion of global carbon emissions, approximately 15% according to Architecture 2030. While building operations, namely heating, ventilation, and air conditioning (HVAC), become electrified and more efficient, it is vital that we turn our attention to measuring and reducing embodied carbon in our buildings by selecting low-carbon, local materials that can be reused or recycled at the end of their life.

Various industry initiatives are addressing embodied carbon in the built environment, including:

- AIA 2030: EC in architecture

- MEP 2040: EC in mechanical, electrical, plumbing, and fire protection (MEP) systems

- SE 2050: EC in structural systems

MEP Embodied Carbon

There are tools and methodologies for measuring the embodied carbon of a building’s architectural elements (substructure, superstructure, interiors, etc.) that are fairly developed. For the embodied carbon of MEP systems, there is much less data and guidance available. To address this gap in industry knowledge, MEP 2040 and the Carbon Leadership Forum have written “The Beginner’s Guide to MEP Embodied Carbon,” a framework and pilot study that serves as a baseline for a select group of firms that have taken on the challenge. Clark Nexsen is joining this cutting-edge initiative by conducting a case study on a cabin design for an educational and wellness campus in North Carolina. The case study will measure both architectural and MEP embodied carbon, contributing to the whole carbon story of the cabin and the greater industry understanding of carbon in MEP systems.

Case Study

A wellness and educational campus in the mountains of Western North Carolina is expanding, and part of this expansion will include the construction of 30 identical cabins for temporary guest lodging. These cabins will be served by a new geothermal system on-site, comprised of two vertical distribution well-fields. The cabin itself is a one-bedroom, one–bathroom residential unit with a small living area, mechanical closet, entry hall, covered outdoor patio area, and a green roof.

Rendering of the guest cabin.

The cabin’s MEP systems are fairly standard for a building of this typology, with the exception of geothermal integration. Each cabin will contain a ducted, ground-source heat pump that will provide zone heating and cooling. An instantaneous water heater will provide hot water via copper supply lines. Each cabin will be served by a 100A, 208/120V, single-phase, three-wire system, with one panelboard serving lighting loads, HVAC equipment, receptacle, and general equipment loads.

The cabin was intentionally designed to be low carbon in its materials and MEP systems. Conducting the embodied carbon study will quantitatively show the impact of those design decisions.

Tools and Methods–Architecture

The embodied carbon of the cabin’s architectural elements was quantified using Tally, a Revit plug-in created by a partnership between KI Innovations, a KieranTimberlake affiliate company; Autodesk; and Sphera. As explained in KieranTimberlake’s article “How can we better understand embodied environmental impacts in order to expand the boundaries of sustainable design?,” Tally integrates BIM data with carbon emissions data. This is a cradle-to-grave analysis, meaning that it will include the product stage, construction stage, use stage, and end-of-life-stage. Each of these stages can have a significant impact on embodied carbon. For instance, shipping a building product across the ocean by barge will have a much higher embodied carbon than a local product that only needs to be driven a few hundred miles.

Image courtesy, Low Energy Transformation Initiative.

Tally contains EPDs for thousands of building products, so it’s just a matter of assigning them to modeled elements. For unmodeled elements, such as reinforcing steel, Tally provides the option to include them in quantities that the user can specify.

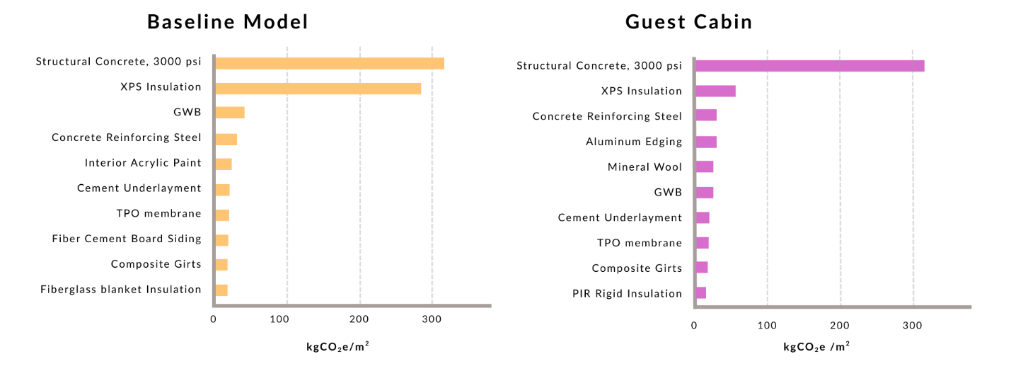

A baseline model was also developed in Tally in order to calculate carbon reductions. This model was identical to the cabin in its physical size, scope and function, but material substitutions were made to reflect industry averages for this building typology and region. For instance, fiber cement board siding was used as the exterior finish in the baseline building instead of cedar plank siding in the proposed design.

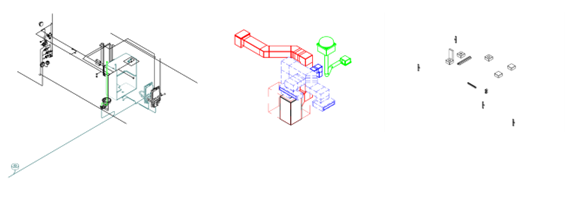

Tools and Methods—MEP

Isolated models of the cabin’s plumbing (left), mechanical (middle), and electrical (right) systems.

Calculating the embodied carbon of the cabin’s MEP systems was largely a two-part process. First, we quantified the exact amounts of piping, ductwork, wiring, insulation, refrigerant, and equipment used in the cabin. Then, we obtained the carbon data for the products and materials specified through EPDs. In general, there is a lack of EPD availability for MEP systems, making this process more difficult than the architectural study. OneClick LCA, an online EPD database, was used to search for and compile product EPDs.

Low-carbon Design

As detailed in Figure 1.1, below, compared to the baseline building, the cabin demonstrated a 73% reduction in embodied carbon, largely due to intentional material decisions made by the design team. Using wood as the main structural and finish material and mineral wool as the exterior wall insulation proved to be large contributors to this reduction value. Selecting local manufacturers for timber products and concrete also reduced the carbon associated with the transportation stage. The cabin even surpasses the International Living Futures Institute’s (ILFI) Zero Carbon Certification benchmark, described in ILFI’s “Zero Carbon Certification Overview,” by 50%. The cabin’s top 10 materials by GWP are shown below, clearly showing that the structural concrete used for the foundation is the most carbon-intensive material in the project.

Figure 1.1 compares the guest cabin to a baseline building.

While concrete cannot always be replaced due to strength and cost factors, ways to reduce concrete embodied carbon include carbon curing, cement replacement, prefabrication, and using recycled aggregates.

MEP Results

Where the architectural study was largely focused on quantifying embodied carbon reductions, the MEP analysis is more about obtaining data and solidifying methods in an area of industry growth.

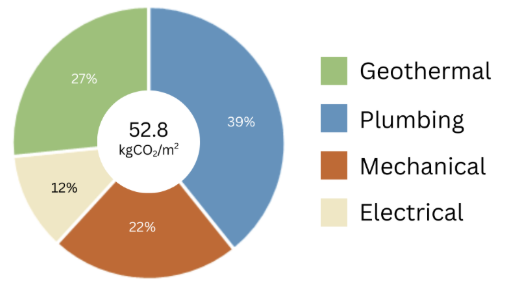

Figure 1.2 details cabin MEP embodied carbon by discipline.

As shown in Figure 1.2, above, the embodied carbon of the cabin’s MEP systems was largely dominated by plumbing due to the use of cast-iron pipes. The geothermal system, which supplies heating and cooling to all 30 cabins, includes vertical piping for the well field, horizontal piping for distribution, 20% glycol solution, silica sand, and bentonite grout. The total geothermal embodied carbon was normalized to reflect its impact for one cabin.

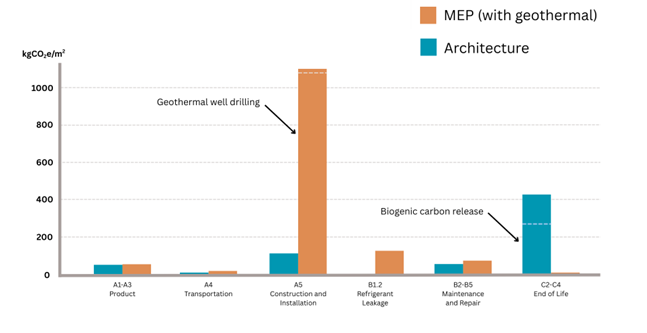

Figure 1.3, below, shows the architectural and MEP results for each life cycle stage of the building, providing a comprehensive understanding of the cabin’s whole life embodied carbon.

Figure 1.3 shows the architectural and MEP results for each life cycle stage of the building.

Drilling for the geothermal wellfield far outweighs the carbon associated with any other stage of the building’s life, so it may be worth looking into alternative fuel types, more efficient equipment or different well field locations.

Moving Forward

With early and often integration, embodied carbon studies can have a significant impact on a building’s materials, structure, and systems. In the case of the cabin design, we were able to confirm that design decisions, especially material selection and procurement, were consistent with low-carbon design standards and aligned with the deep sustainability goals of the project. The embodied carbon results from the cabin’s MEP systems will contribute to a growing base of knowledge for MEP carbon and create demand for increased EPD availability and measured project data.

Ollie Fast (they/them) is a Sustainability Coordinator at Clark Nexsen and a former Clark Nexsen Sustainability Student during the summer of 2025. As an emerging professional, Ollie aims to not only reduce the negative impacts of buildings and structures but also explore how the built environment can affect positive, circular change in local and global communities.To get in touch with Ollie, please email ollie.fast@clarknexsen.com or call 757.961.7809.